In early 2020, the world has a monopoly on the threat of the COVID-19. Because the virus is highly contagious, has a long incubation period, and causes damage to the lungs after infection, governments worldwide are making people wear face masks compulsorily in enclosed spaces. Even though manufacturers are trying to expand their production capacity, people are still panicking and buying face masks. At a time when most of the industrial economies are suspended, the production and sales of masks grew against the odds.

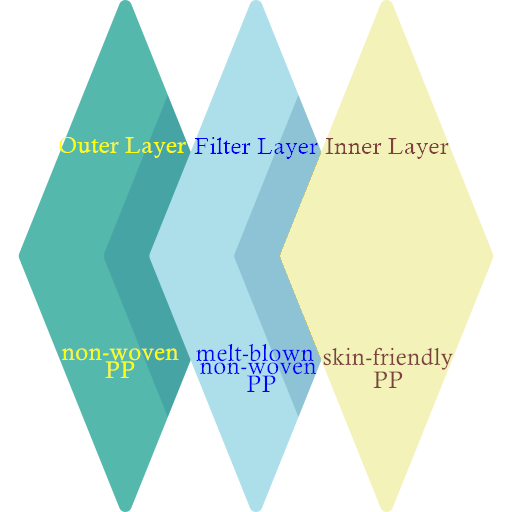

The masks we currently purchase are other medical masks (Class I medical devices). Typically, there are three layers, which perform the following functional roles.

Outer Layer – It is a non-woven PP layer, and has a water repellent treatment to reduce its surface tension. The primary function is to prevent the adhesion of droplets or blood with pathogens. The diameter of the non-woven fiber is thicker than the middle layer (filter layer), making the pores between the non-woven fabrics larger.

Filter Layer – It is a high density melt-blown non-woven PP layer. Using a very low viscosity PP material, excellent fibers are squirted out at high speed. These fibers interact and stack with each other with tiny pores, effectively filtering out bacteria and viruses. Sometimes, some electret materials will be added to make the melt-blown layer have more static electricity and not dissipate quickly. Through the above dual-function design, the middle layer can effectively filter out 90% of the 5-micron particles, so most of the viruses and bacteria can be trapped here.

Inner Layer – This is a skin-friendly PP or PE layer, without water repellent treatment. The primary function is to absorb saliva and sweat from the wearer’s mouth to improve comfort when wearing the mask for long periods.

Another commonly heard type of mask is the N95, which is a NIOSH classification. N stands for filtering non-oil particles, and 95 stands for filtering more than 95% of the particles. 0.075±0.02μm size particles are used in the certification test. The European Union’s test standard is EN149, and the class classification is FFP2. Therefore, all N95 masks sold in the market claimed to be effective in filtering more than 95% of the airborne particles above 0.3μm, which includes most of the bacteria and viruses. However, the disadvantages are higher prices and poor breathability, making it more suitable for professional medical staff. The governments are also actively promoting standard medical masks so that medical resources can be used most effectively.

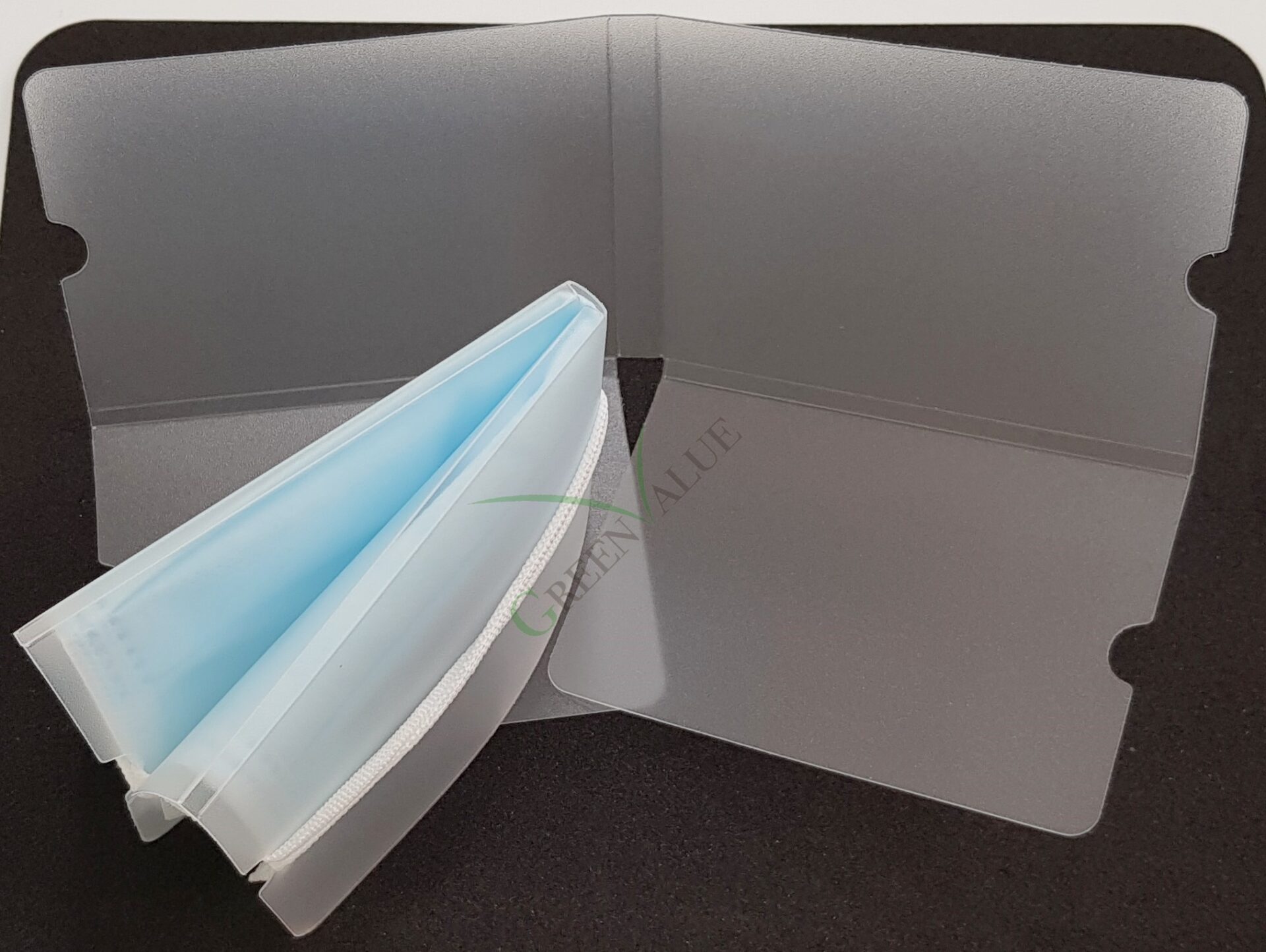

Green Value can integrate the general medical mask and N95 mask production lines. We can provide high-MI melt-blown grade PP pellets, electret masterbatches, melt-blown equipment, and mask production machines. If you are interested in knowing more, please feel free to talk to us.

Ask for a quote: Melt-blown grade PP Pellets, Electret Masterbatches, Melt-blown Equipment, Mask Production Machines, Medical Masks