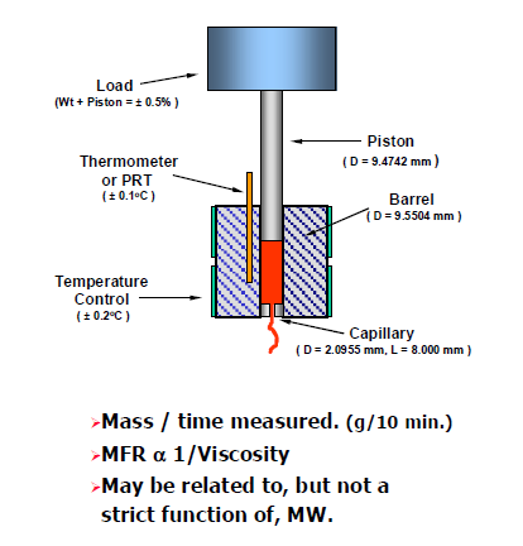

Melt flow index, also known as MI or MFI, is an essential measure for the ease of flow of the melt of a thermoplastic polymer under a specific standard temperature. ASTM D1238 standard had defined the measuring method and device as below figure.

Practically preheat the device to the desired temperature and bake the testing sample by the meantime to reduce its humidity. Once the target reached, load the sample into the preheated cylinder then covered by a piston. According to the material type and introduce a specified weight load onto the piston. Ensure the sample is molten after the desired period time before removing the insulating plate. The molten polymer then starts extruding through the die orifice (capillary with a 2.0955 diameter and an 8.000 length). Check the extrudate flow and adjust the cutter speed accordingly. Weigh the extrudate per minute and multiply ten times to obtain the MI. The MI can be expressed in g/10 min (grams of polymer per 10 minutes of duration of the test).

Based on the test procedure, we can tell that if the sample is more viscous, the extrudate will be less; in other words, the smaller MI it will be. (The concept is different from a viscometer, while a bigger index stands for more viscous.) MI is now widely used as an essential reference for choosing the procedure and product used for it.

Generally speaking, samples with higher viscosity (MI<2) are more suitable for blow molding, extrusion, and sheet making. In contrast, samples with lower viscosity (MI>10) are more suitable for injection molding.

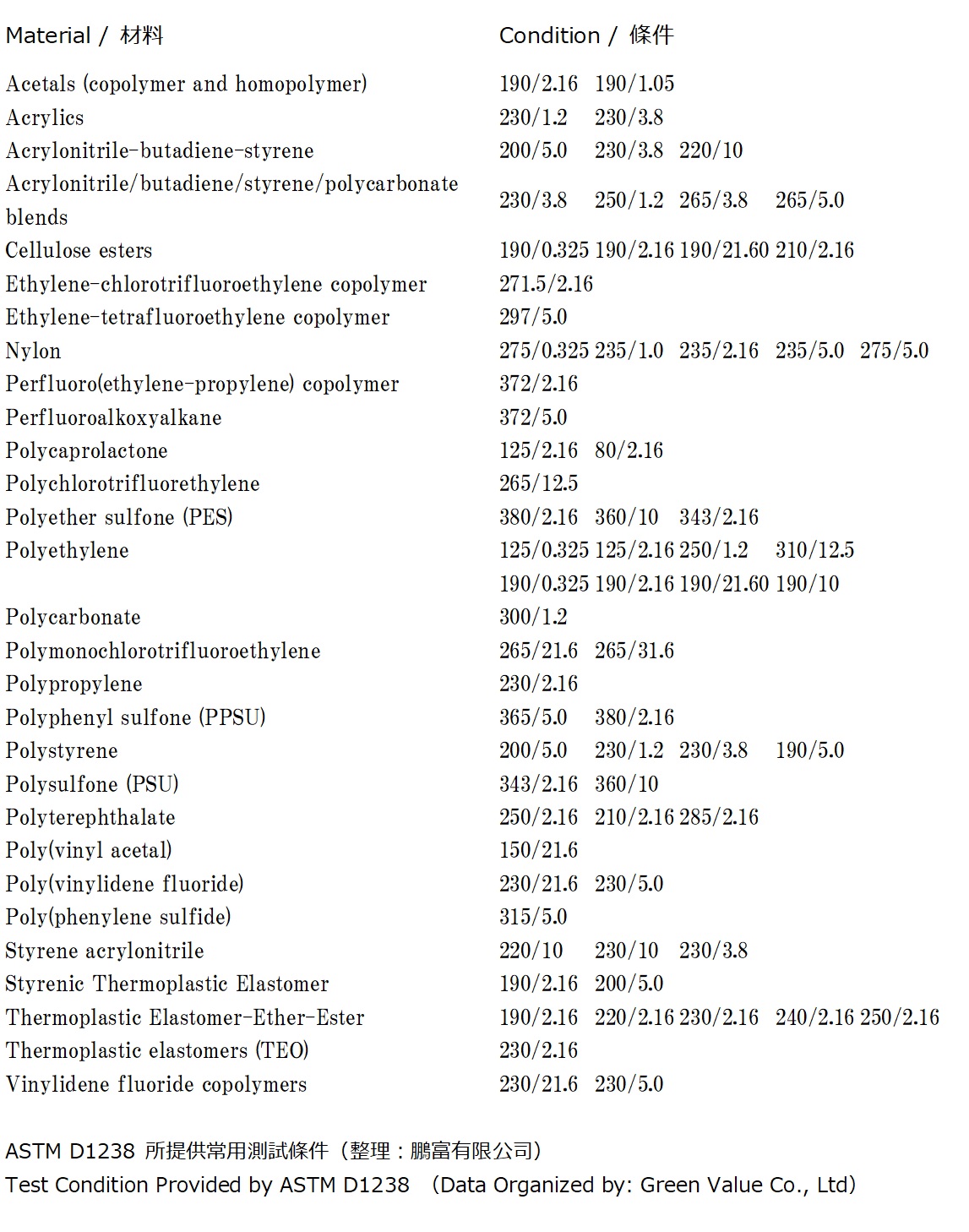

However, MI can also be confusing. The same index may refer to different temperatures and loading weight conditions. For instance, when it goes to PP (polypropylene), some of them are tested under 2.16 Kgs/ 210℃, while some are tested under 2.16 Kgs/ 190℃. Even for the same material, the index can only be compared under the same temperature and loading weight. If the testing temperature is higher or the load is more substantial, the extrudate from the capillary will be more. This refers to a higher MI and vice versa. Before comparing the MI, assure the conditions are the same will be necessary.

Ask for a quote: Plastic Material, Plastic Additive, PP, PE, PS, ABS, POM, POM, TPU, TPE, PVC, Phenolic resins